DC Motor

Updated: 6/28/2025 Words: 0 words Reading time: 0 minutes

A DC motor is a simple, two-wire electrically controlled device with a rotating shaft on which wheels, gears, propellers, etc. can be mounted. By reversing the polarity applied to the wires, the DC motor can rotate clockwise or counterclockwise. DC motors can start, stop, and reverse quickly, and speed can be precisely controlled.

Preparation

| Hardware | Description | Image |

|---|---|---|

| Creative Box Platform |  | |

| H-Bridge DC Motor Driver | Taobao Purchase Link | |

| DC Motor | Taobao Purchase Link |

Video Tutorial

Driving DC Motors

Connection

Usage

Principle

When a current-carrying conductor is placed in a magnetic field, mechanical force is generated. The direction of this effect can be determined by the left-hand rule. By changing the current intensity in the motor windings or the supply voltage, we can control the speed of the current-carrying conductor.

Types

DC motors can be classified as brushed or brushless based on how the rotor is powered. In brushed DC motors, current is applied to the rotor through brushes. In brushless DC motors, the rotor is a permanent magnet.

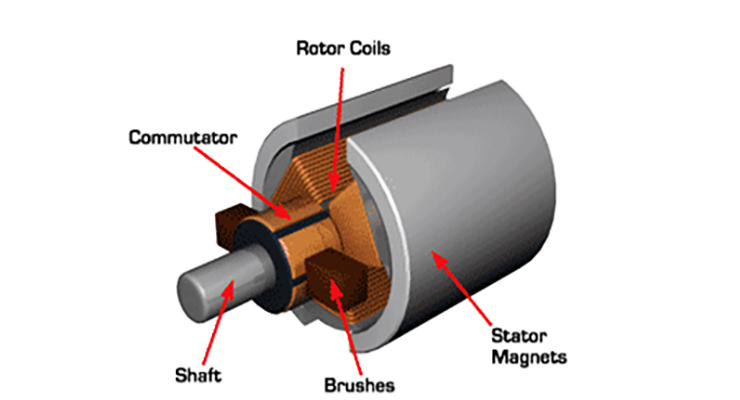

Brushed DC Motor

In a brushed DC motor, the motor's stator contains the shaft and the housing for the magnetic field, while the rotor contains coil windings.

Current is applied through brushes, and the magnetic field is generated by the current flowing through the brushes and the commutator connected to the rotor. The commutator is an electrical switch that reverses the current between the rotor and the external power source.

When a brushed DC motor rotates, the brushes and commutator maintain continuous contact. This continuous contact causes wear, so brushed DC motors have a shorter lifespan and require regular maintenance. Additionally, the continuous contact between brushes and commutator also generates electrical and acoustic noise during motor operation.

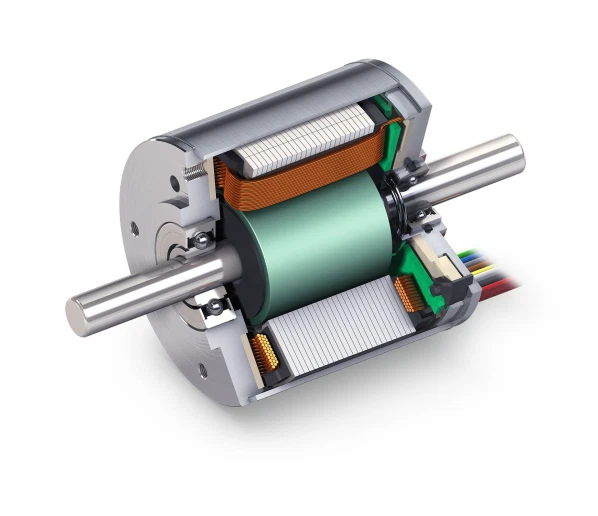

Brushless DC Motor

Brushless DC motors include a magnet rotor and a stator with a series of coil windings. Brushless DC motors do not rely on vulnerable commutators and brushes, so they have longer lifespans and are quieter.

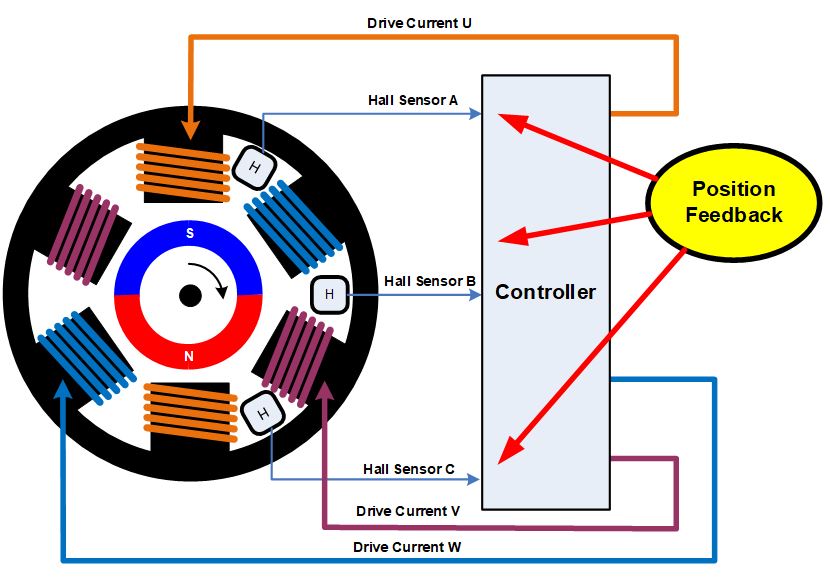

Brushless DC motors typically have three coils, each connected to semiconductor switches. Opening and closing these semiconductor switches in the correct sequence alternates current flow, creating a rotating magnetic field that causes motor rotation.

To control the rotation sequence of each coil, brushless DC motors require a drive circuit to operate. Additionally, the direction of the permanent magnet rotor can be detected through magnetic sensors (usually Hall sensors) to switch the semiconductor switches.

Speed Control

DC motors can provide any rotational speed between 3000 and 8000 RPM at specific operating voltages (1.5~24V). Reducing voltage can slow it down, while increasing voltage can accelerate the motor. However, when the applied voltage drops to about 50% below the specified operating voltage, the motor usually stops rotating. Conversely, if the applied voltage exceeds about 30% of the operating voltage, the motor may overheat and be damaged.

In practice, DC motor speed is most effectively controlled through Pulse Width Modulation (PWM), where the motor is rapidly turned on and off. The width of the applied pulses and the period between pulses control the motor's speed.

A freely rotating motor (no load) draws less current (power), while after applying a load, the amount of current drawn by the internal coils of the motor increases significantly. Manufacturers typically provide a "stall current" rating for their motors, which indicates the force the motor can apply to a load. Torque ratings are usually given in pounds/feet, grams/centimeters, or ounces/inches.

Sensor Sparks

Sensor Sparks