Servo Motor

Updated: 6/28/2025 Words: 0 words Reading time: 0 minutes

A servo motor is a type of motor that can precisely control position, speed, and acceleration. They are typically used in conjunction with feedback systems to achieve highly precise motion control.

Meaning of Servo

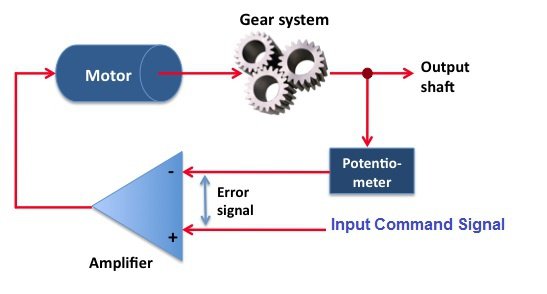

A servomechanism, often simply referred to as a servo, is a specialized automatic control system designed to control the position or motion of an object. It consists of four main components:

- Input Command: The desired position or motion that the system needs to achieve.

- Feedback: The system continuously receives feedback on the actual position or motion of the controlled object. This feedback is used to compare with the input command and make necessary adjustments.

- Power Amplification: The system includes a power amplification mechanism that can increase the power or force applied to the object, ensuring it can achieve the desired position or motion.

- Output: The output is the result of the system's control, usually the movement or positioning of the object.

Servomechanisms are widely used in various applications that require precise control of position or motion. They are commonly found in robotics, aerospace systems, industrial automation, automotive systems, and other fields where precision and responsiveness are crucial. The feedback loop in a servomechanism allows it to continuously adjust and correct deviations from the desired position, ensuring accurate and stable control.

Internal Structure

A servo motor has three leads. One for power, one for ground, and the third is the control lead. Since a servo is a closed-loop feedback system, the control lead is needed to sense the position of the servo shaft and make adjustments when necessary.

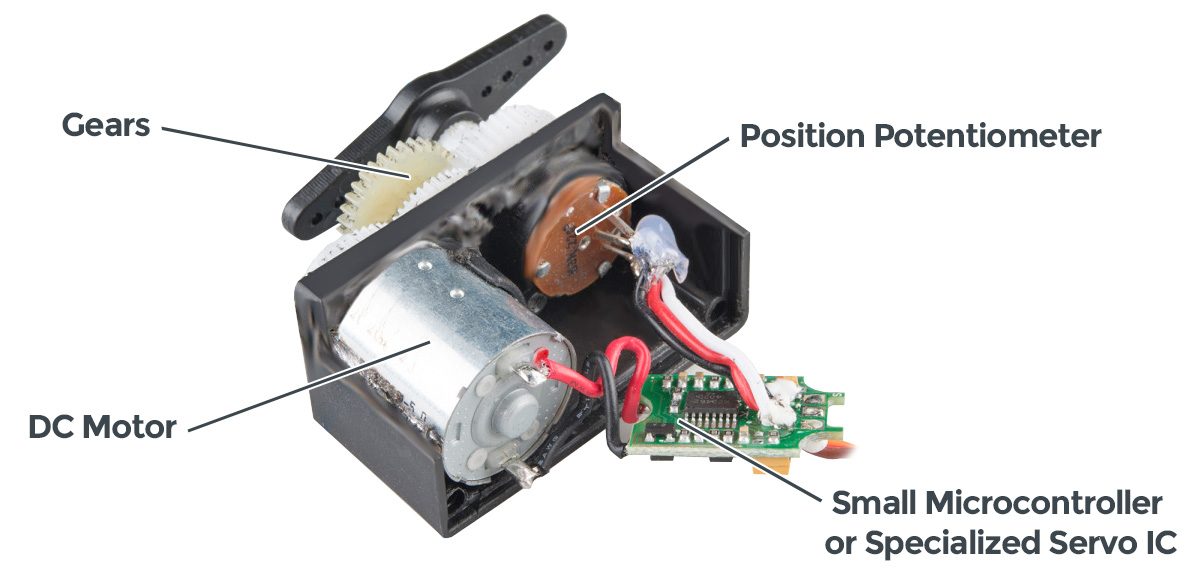

A servo motor contains at least three main parts: a DC motor, reduction gears, and a control circuit.

DC Motor

The DC motor is responsible for changing direction. In the diagram above, it's the silver part.

Reduction Gears

These gears reduce the high speed of the DC motor to a speed suitable for fine control. Because of these gears, multiple rotations of the motor equal one rotation of the servo shaft. The black part with holes on the casing is the servo horn. Horns are used to attach rods and other items to the servo motor. They come in various shapes and sizes.

Control Circuit

The servo's output gear is connected to a potentiometer (the brown object in the diagram above), which is a variable resistor. The position of the potentiometer indicates the position of the servo motor shaft. There is also a small board with some circuitry that reads the potentiometer and controls the servo.

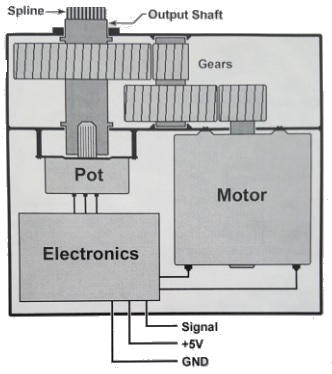

The diagram below is a typical internal schematic of a servo motor:

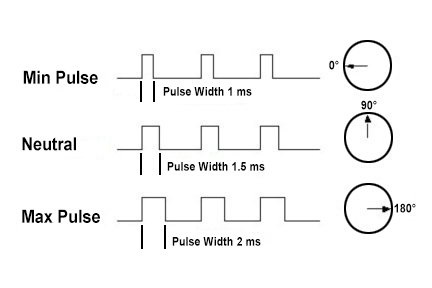

Control Signal

Servo motors are typically powered by 4.8 to 6 volts. In addition to this, they require special control signals. The signal that controls a servo motor's operation is a series of electrical pulses. What determines the servo's position is the exact length or duration of the pulse. It's not the number of pulses per second that controls the servo; rather, it's the duration of the pulse that controls it. This is what makes servo control slightly different from PWM. Therefore, it is more accurate to refer to servo control as pulse duration modulation.

The duration of the pulse is typically 1 - 2 milliseconds. A 1-millisecond pulse will cause it to rotate in one direction, a 1.5-millisecond pulse will return the servo to its midpoint, and a 2-millisecond pulse will cause it to rotate in the other direction. The typical range of motion for a servo is 0 to 180 degrees, or close to that range.

Typically, servo motors require about 50 such pulses per second, which is referred to as the servo's refresh rate or frame rate. If this rate is too low, accuracy and holding torque will decrease. If too high, the servo may jitter or not function properly.

Parameters

Servo motors adhere to several standards, one of which is the size of the casing.

Standard-sized servo motors measure approximately 1.5 inches x ¾ inches x 1 3/8 inches, with a mounting flange containing four holes. Large-sized servo motors are about twice the size of standard servos and are more powerful. Therefore, they are suitable for robotic movements. Mini and micro servo motors are half the size of standard ones or smaller, suitable for use in confined spaces.

In addition to size, torque is another important parameter. It is usually given in inch-ounces, either at 4.8 volts, or at both 4.8 volts and 6 volts.

Speed is the time it takes for the motor to rotate through a given angle (usually 60 degrees).

Sensor Sparks

Sensor Sparks